LVT Flooring Production Experience.

A multi-layer construction process is used to create Luxury Vinyl Tile (LVT) flooring, which guarantees both visual appeal and longevity. A sturdy vinyl backing layer serves as its foundation, offering stability and strength. A vinyl core, which increases flexibility and resilience, comes next. The next layer is called design, and it has high-resolution photos that mimic the appearance of real materials like stone or wood. After that, a translucent wear layer is added to provide defense against fading, scuffs, and scratches. The layers are fused together by applying pressure and heat to the entire assembly. For added longevity and simplicity of maintenance, certain LVTs are also coated with urethane.

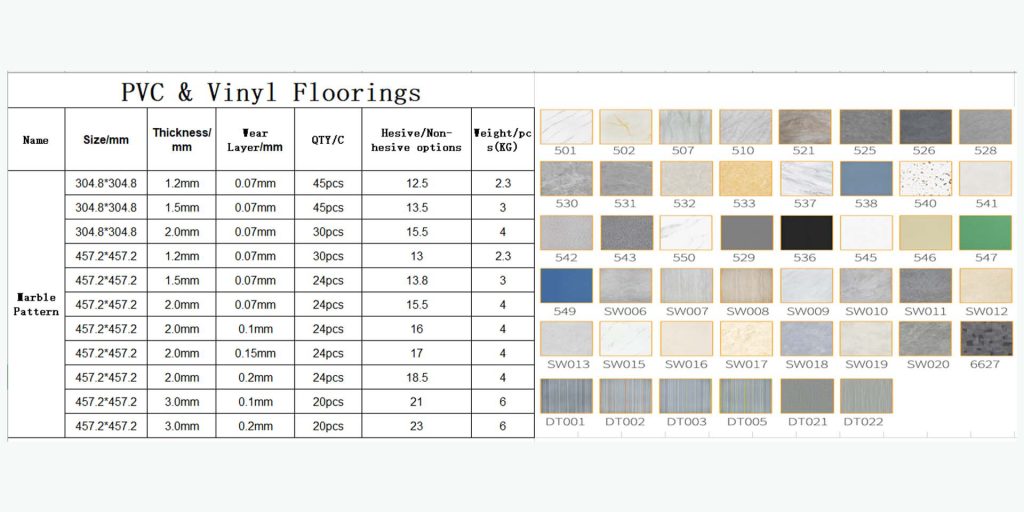

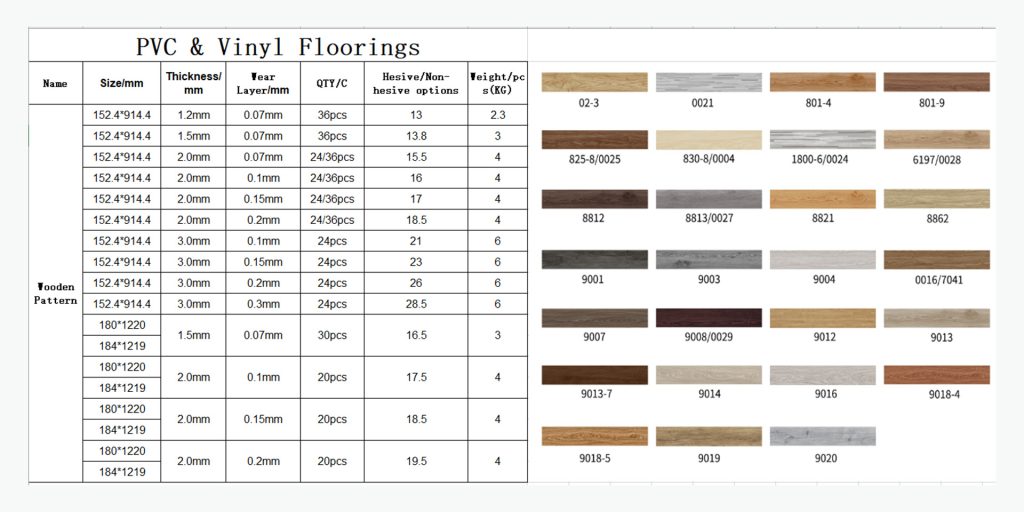

The thickness and dimension of LVT flooring affect its price; additional factors that affect the price include special requirements and customized specifications.

A naturally occurring mineral called calcium carbonate is the primary raw material used in the production of many kinds of flooring, particularly vinyl-based goods. Mostly made of limestone, it gives flooring materials a lot of advantageous qualities. Its incorporation during the manufacturing process gives the flooring increased stability and longevity. This is especially important in areas where there is a lot of foot traffic or longevity is desired. Furthermore, calcium carbonate adds a smooth texture that enhances the overall visual appeal. Its affordability and eco-friendliness further solidify its status as a manufacturer’s choice, satisfying the flooring industry’s need to balance economic and environmental concerns.

Precise manufacturing techniques and cutting-edge materials engineering are combined in the creation of Luxury Vinyl Tile (LVT). Polyvinyl chloride (PVC) resins are first combined with plasticizers to provide flexibility and other additives to provide durability. A backing layer for stability, a core layer, an aesthetically pleasing high-definition photographic print layer, and a transparent wear layer for protection are the layers that make up the construction. Calendaring is the process by which these layers are heated and compressed together to form a bond. Using digital printing technology, intricate designs are applied before a transparent, durable coating is applied. After being cut to size, the finished tiles go through quality inspections to make sure they adhere to strict requirements for environmental safety, durability, and aesthetics.

The goal of quality control (QC), a crucial procedure in business and manufacturing, is to keep goods and services up to the required standards. To make sure the finished product satisfies predetermined standards, it entails routine testing and inspection at different phases of production. Defects or variations are found by effective QC, allowing for prompt remedial action. This process is based on a set of standards and standard operating procedures that represent industry regulations and client expectations. Businesses strive to reduce errors, improve customer happiness, and maintain their reputation by putting strict quality control procedures into place. A strong quality control system must have ongoing monitoring and improvement.

Use a soft broom or a vacuum with a soft brush attachment to remove any loose dirt for a thorough cleaning. A moist mop combined with a light detergent is ideal for stubborn stains. Avoid using strong chemicals at all times to preserve the floor’s finish. A matching floor repair kit can quickly cover up little fixes like scratches. Larger problems can frequently be repaired without completely replacing the floor by replacing individual tiles or planks. Frequent upkeep, such as applying furniture pads and quickly wiping up spills, helps shield the floor from harm and preserves its best appearance.

Experience Elegance: Putianshuo LVT Flooring is Stylish, Long-Lasting, and Ideal for Contemporary Spaces. Wholesale Prices for International Companies.

Putianshuo’s Luxury Vinyl Tile (LVT) Flooring combines enduring quality with aesthetic appeal, offering an ideal solution for diverse spaces. Our LVT flooring, known for its robustness, withstands heavy foot traffic while maintaining its elegant look. Each tile replicates the beauty of natural materials like wood or stone, yet provides superior comfort underfoot. Its moisture-resistant nature makes it perfect for humid environments. Installation is effortless, and maintenance is minimal, ensuring a long-lasting, pristine appearance. With Boyu’s commitment to sustainability, this eco-friendly option is a top choice for environmentally conscious businesses. Embrace the blend of functionality and style with Boyu’s LVT flooring.

Putianshuo’s LVT flooring enhances the visual appeal of any place by combining style, durability, and ease of maintenance. It is perfect for homes, offices, and commercial spaces.

Luxury Vinyl Tile (LVT) flooring is a durable, high-quality vinyl flooring option designed to mimic materials like hardwood and stone.

Our LVT flooring is extremely durable, resistant to scratches, stains, and water, making it suitable for both residential and commercial use.

Yes, Putianshuo LVT flooring is designed for easy installation, with options for glue-down or click-together tiles and planks.

Absolutely, LVT’s water-resistant nature makes it ideal for bathrooms, kitchens, and basements.

Maintenance is simple – regular sweeping and occasional mopping with a mild cleaner will keep your floors looking new.

We prioritize sustainability, producing LVT with eco-friendly materials and processes, ensuring a reduced environmental impact.

If you are still wondering how to choose a good supplier, stop and contact us, we will speak with our best service and product quality.

Copyright © 2024 PUTIANSHUO. All Rights Reserved.